Binocular laser triangulation sensors (series LD2.2)

|

Binocular laser triangulation sensors, series LD2.2: A special series of sensors for working with complex surface relief. Owing to two sensors symmetrically located relative to the laser beam, the binocular sensor is able to work with a deeper relief without signal loss.

The sensors are designed for use in automation systems and contactless measurement of different geometric parameters: thickness, straightness, inner and outer diameters, scanning the profile of objects with complex forms, determining the position of objects. On the basis of the sensors, a system of automatic control of different processes can be built. In addition, the sensor has the ability to connect the positioning signals from the machines for the realization of 3D scanning systems.

|

SENSOR SPECIFICATIONS: |

|||||||

|

||||||||

EXAMPLES OF USE OF THE LASER SENSOR: |

||||||||

|

|

|||||||

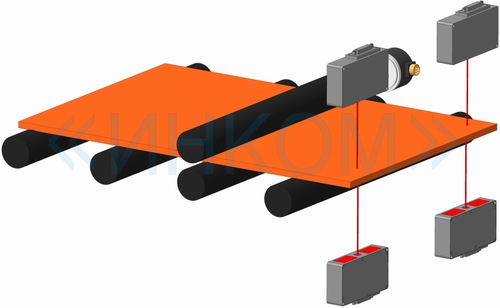

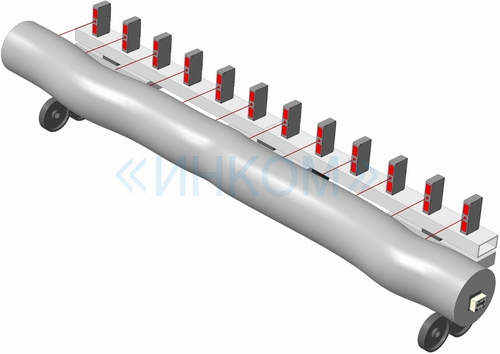

Straightness measurement system |

||||||||

Thickness measurement systemfor sheet articles |

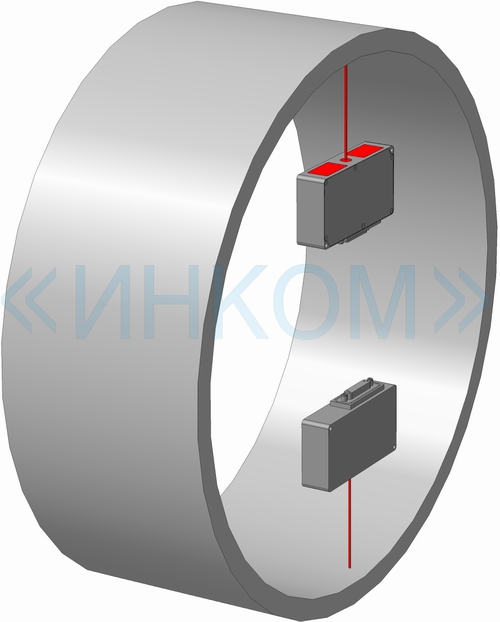

Internal surface inspection,diameter measuring |

|||||||

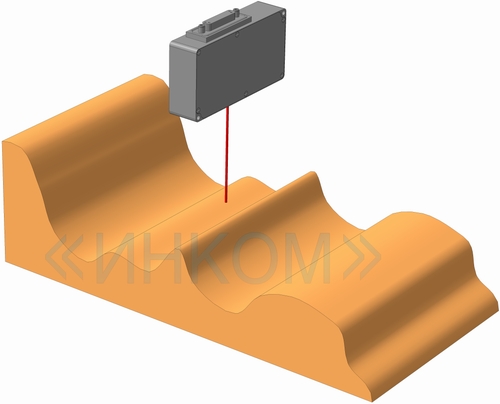

Profile measuring |

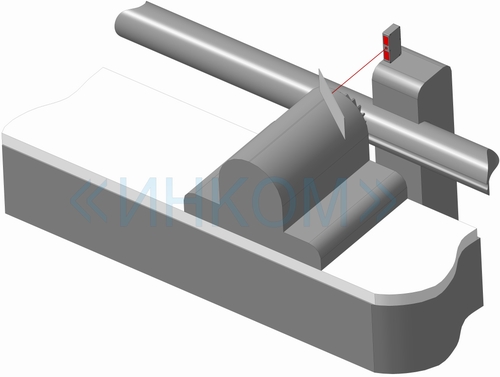

The laser sensor controls the movement of the mill supporting lunette |

|||||||

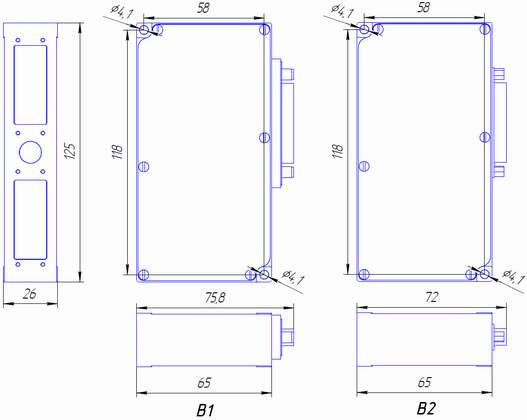

OVERALL AND MOUNTING DIMENSIONS: |

||||||||

|

B1 - Enclosure IP67; B2 - Enclosure IP60; |

||||||||

|

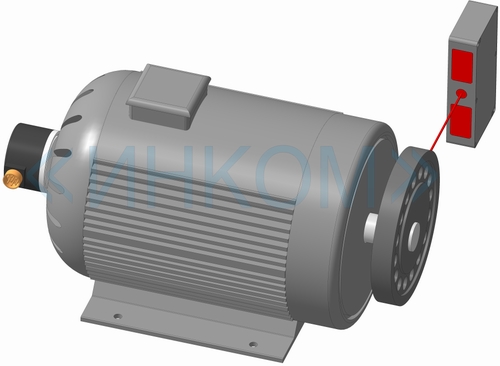

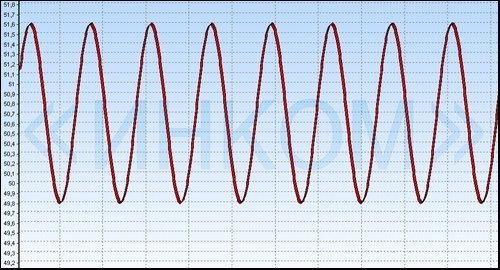

Measurement of runout, vibration displacement, and frequency |

||||||||

|

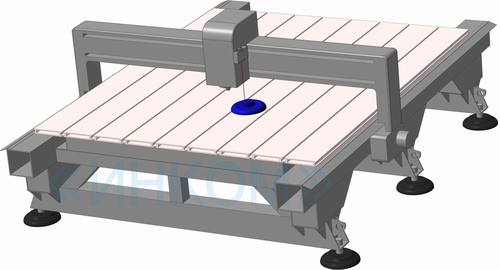

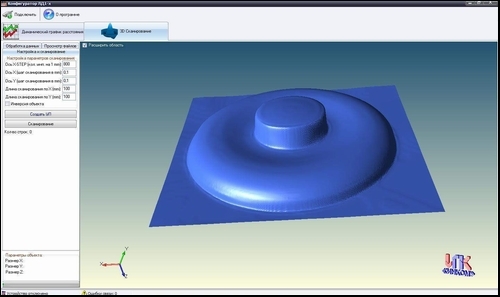

Laser 3D scanner based on a CNC machine |

||||||||

|

|

||||||||

EXAMPLE OF 3D SCANNING 1: |

DOWNLOAD: |

|||||||

|

Scannable model |

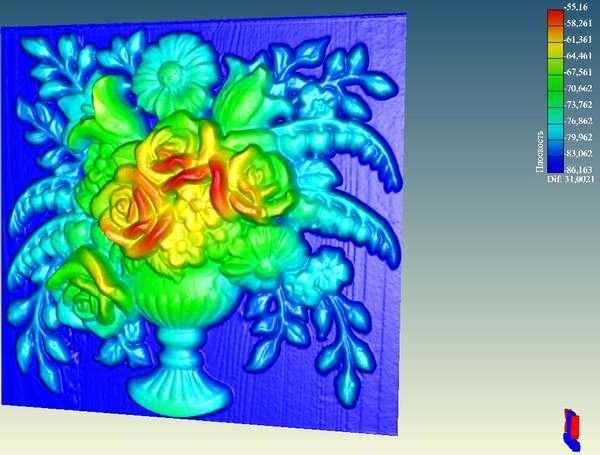

The result of 3D scanning |

User manual.pdf | ||||||

| Instructions for creating a 3D laser scanner.pdf | ||||||||

| Software (x32) | ||||||||

| Software (x64) | ||||||||

| Example of 3D scanning 1 (original) | ||||||||

| Example of 3D scanning 1 (filtered) | ||||||||

| Example of 3D scanning 1 (filtered) | ||||||||

| Example of 3D scanning 2 (original) | ||||||||

| Example of 3D scanning 2 (filtered) | ||||||||

| Example of 3D scanning 2 (filtered) | ||||||||

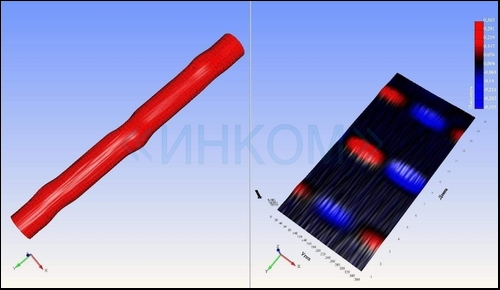

EXAMPLE OF 3D SCANNING 2: |

||||||||

|

|

|

|

|

|||||

| Scannable model | The result of 3D scanning | Analysis of depth of a relief 3D model | ||||||

VIDEO: |

||||||||